Small Volume Plating Cell

To optimize electroplating solutions NBT has constructed a testing cell for volumes less than three litres. Working with such small quantities during the development process of electrolytes allows the variation of different compounds without wasting large amounts of material.

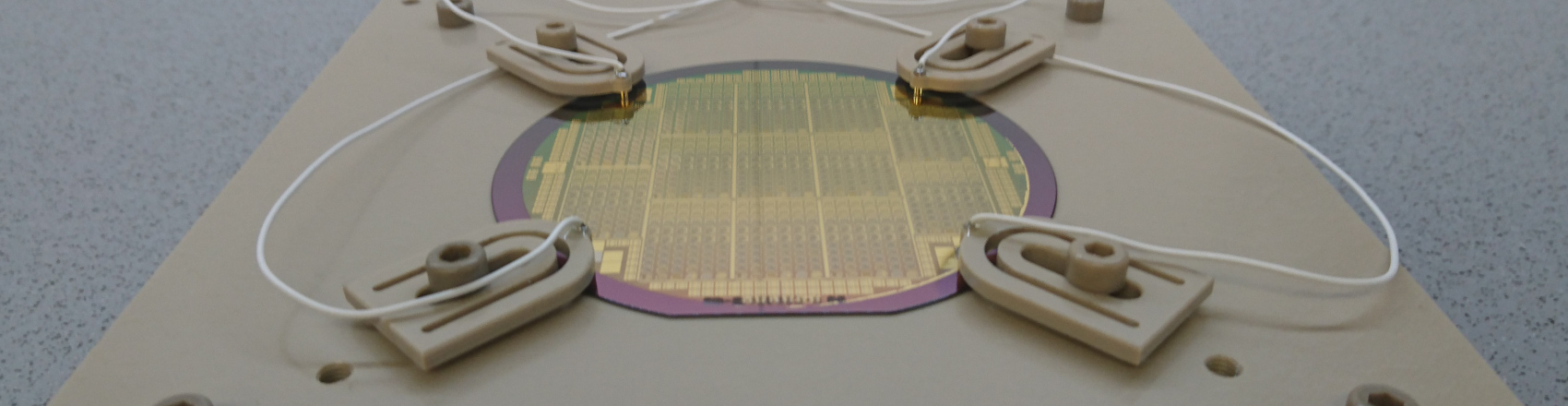

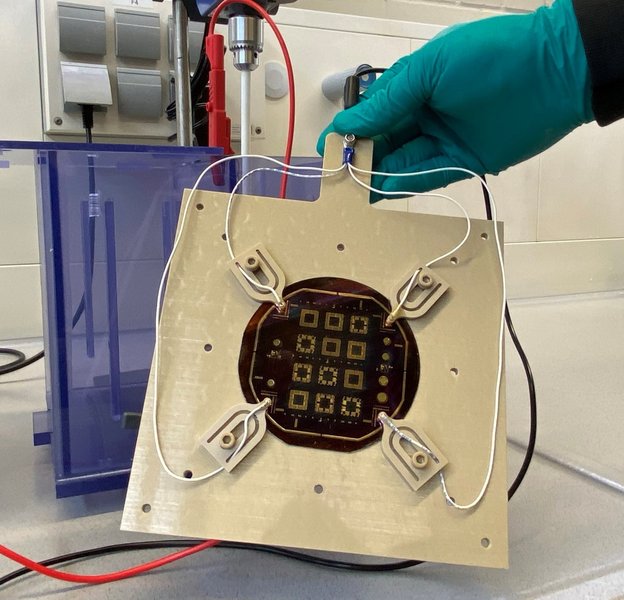

NBT offers the testing cell along with a wafer holder which enables either front side bonding at the outer edge or backside contacting.

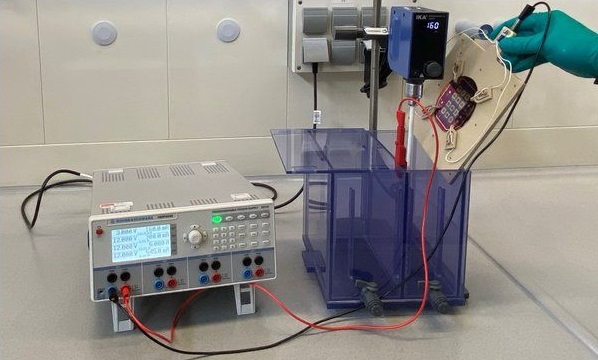

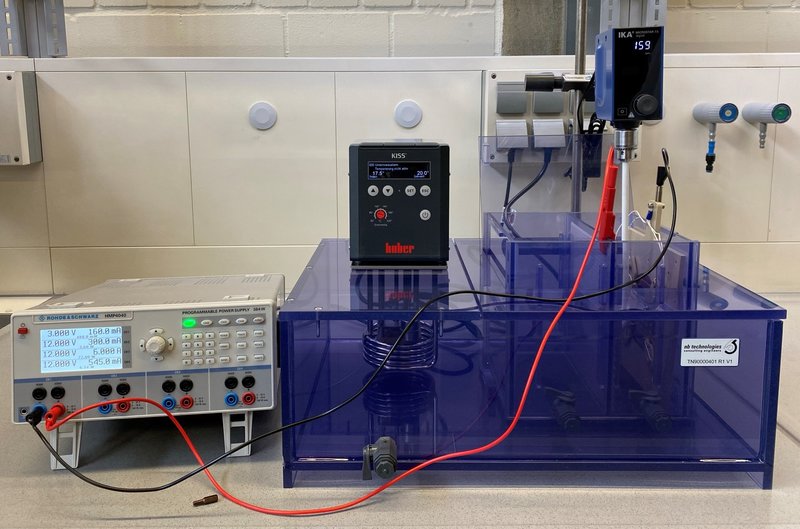

Basic setup:

small volume test cell (3l), anode, wafer holder

Accessories:

high power LED field with light control unit, power supply, overhead stirrer, temperature control bath

small volume test cell applications

- Plating of solar cell metallization

(front side/backside; plating on seed/directly on silicon)

- Silicon direct plating, e.g. in combination with porous silicon

+ silicide formation without emitter shorting

+ single cycle of dry/wet/dry (silicide after full stack plated)

- Plating on high ohmic emitters

- Wet chemical / electrochemical processes such as texturation, cleaning, anodisation, etching

main benefits

- single side/backside dry processing

- no need for backside protection -> high flexibility in chemical processing

- processing with up to 25% HF, e.g. porous silicon

- different holders for changing the wafer size or contacting configuration

- light induced or supported processes