suncup®

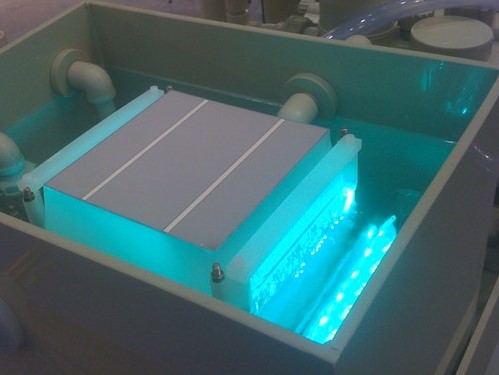

The suncup® plating lab tool is a key component for innovative concepts in solar cell metallization using electroplating. The suncup® works as a fountain plater with the process side facing down. Substrates are processed on one side without a holder, and the back side remains dry during the process. In addition to electrochemical processes, wet processes can be carried out without restrictions through or for the reverse side.

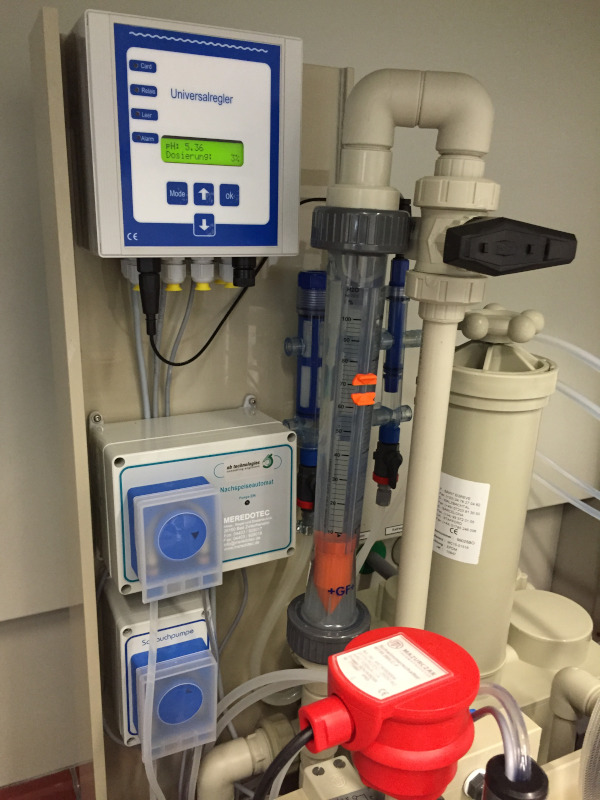

The suncup® is modular in design and offers great flexibility in terms of wafer formats and contacting options. The crown, which determines the overflow and also contains the contacts, is connected to the cup by a simple snap-in solution.

A wafer holder is not required. Wafers are simply placed on the suncup® where they align themselves.

The backside of the wafer remains dry, so carryover of the medium is minimal.

Chemical and electrochemical processes can be supported by light using the optional LED illumination.

The suncup® offers excellent homogeneity with regard to the flow conditions on the substrate.

Basic scope

- Electroplating on solar cells, application on front/back side directly on the start layer (silicon)

- Silicon direct deposition

- Nickel-Silicide formation without emitter short circuit

- Easy change between dry and wet

- Electroplating on high resistance emitters

- Wet chemical/electrochemical processes such as texturing, cleaning, anodizing and etching

Advantages

- Single-sided processing with dry reverse side

- No backside protection necessary -> high flexibility for chemical processes

- Processes with up to 25% hydrofluoric acid, e.g. for porous silicon in the range of 5% to 25% HF

- Modular tool design (anode basket, flux cell, crown for different wafer sizes, contacting)

- Changeover for other wafer sizes and contact configuration with click device

- Light support can be integrated

- Homogeneous flux operations

- Electrical contacts easy to demetallize or dry

- Dry wafer handling (optional for online book detection)

- Lean production techniques and scalability for production lines