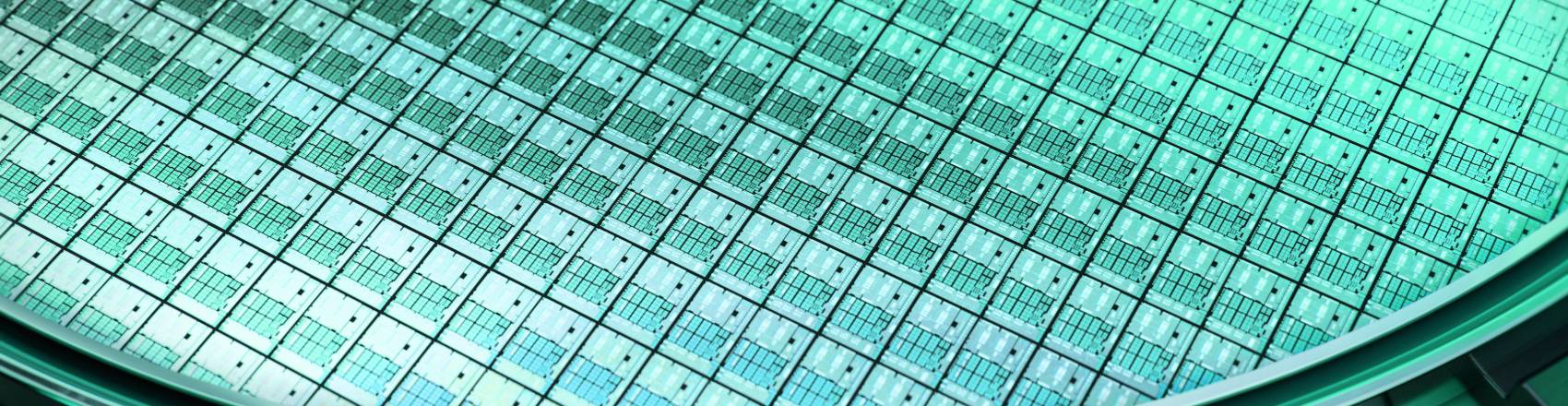

Semiconductor technology - development and manufacturing

NB Technologies is a specialist in semiconductor technology, providing services such as semiconductor circuit design and manufacturing.

Electronics and semiconductor companies need software based on best practices that enable them to develop products and bring them to market.

A holistic approach is required to enable shorter innovation and development cycles, cross-sourcing collaboration, and an intelligent, integrated manufacturing environment.

However, short product life cycles, seasonality in demand as well as intense competition and increasing individualization of end users leave little time for the development of optimal processes in electronics manufacturing

Through Glass Via (TGV)

- Low-resistance metal-glass vias (<10mOhm)

- Gold or copper metallization

- Enables glass wafer capping technology for RF and other applications where low capacitance is critical

Through Silicon Via (TSV)

- Vertical feedthrough adapted to the temperature coefficient for high reliability

- Hermetic, vacuum-tight electrical vias

- Arbitrary shape, maximized electrode area

- Silicon electrode, no metal electrode required, simplifies design and enables high-temperature bonding and post-processing

Electroplating

- Galvanized metals and solders

- Cost-efficient production of thick metal layers (up to 50µm)

- State-of-the-art electroplating equipment for high volume production

Wafer Bonding

- Several bonding technologies available

- Fusion bonding

- Anodic bonding

- Eutectic bonding

- Thermocompression bonding

- Polymeric bonding

- Wafer-level packaging at low temperatures (<300°C)

- Functional IR caps with optical coatings, lenses and getters

- Solder joints to match surface topology (e.g. CMOS wafers)

High Precision RIE

- Multilevel structures combined with fusion bonding and SOI wafers

- High aspect ratio features for comb drive actuation and sensing

- Excellent dimensional control of suspension features for stiffness control and frequency specifications in moving structures

- Very low sidewall roughness for mirror applications Profile control <1°, aspect ratio up to 50:1

AuSn Bumping

- Electrodeposited AuSn solders with high precision

- Thin solders with excellent thickness control

- Barrier enables zero outflow on Au metallization

- Solder properties adaptable to the soldering process